White Paper:

Selecting Nest Materials

for Optimal Breeder Layer Productivity

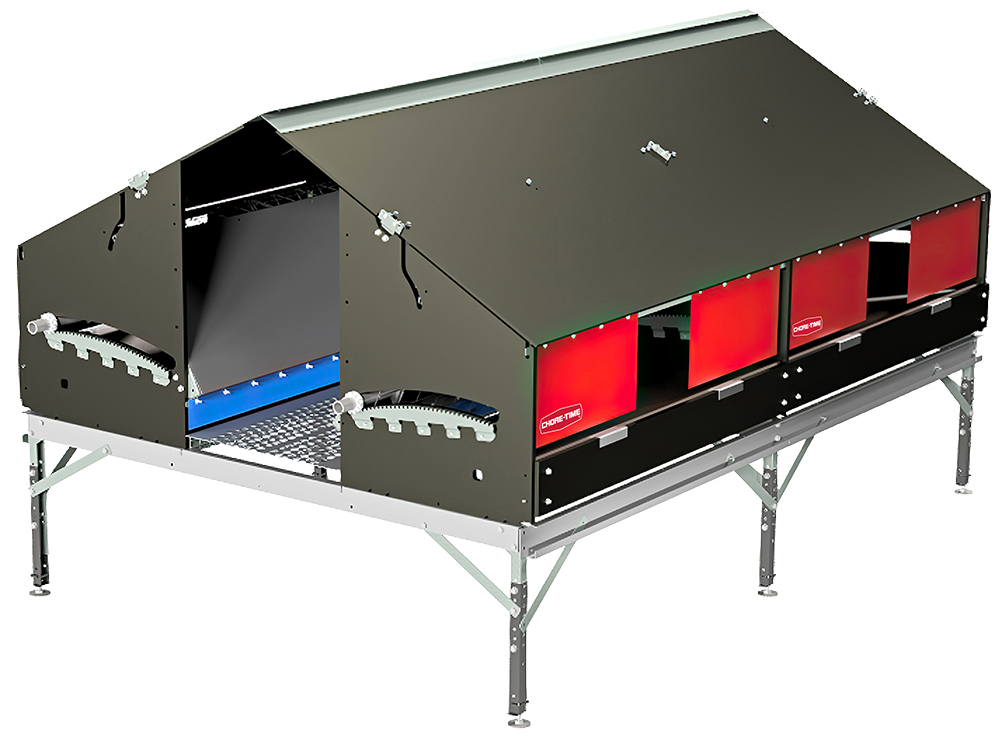

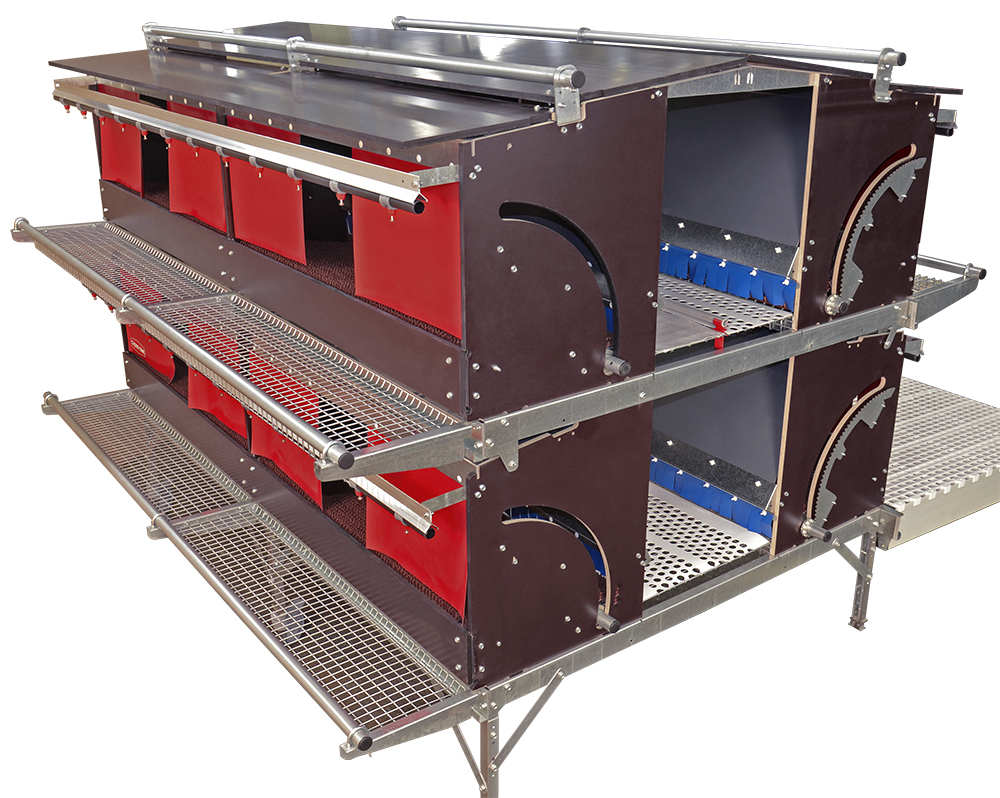

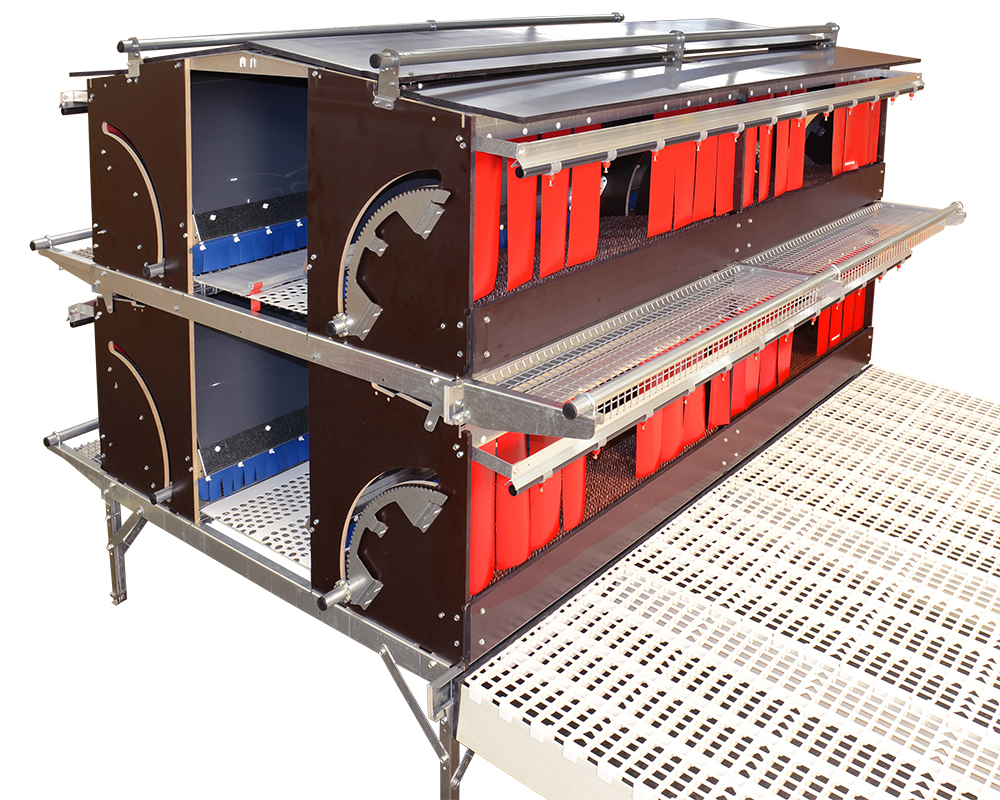

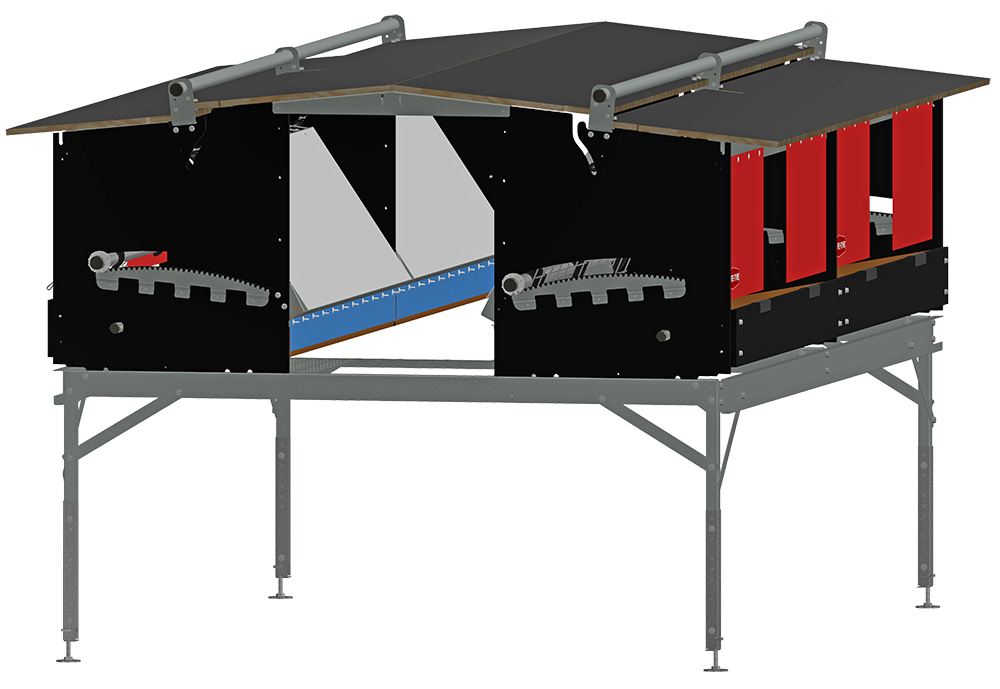

Today’s growers are presented with multiple nest options for their layers. They can choose nests made of film-faced plywood, plastic or metal. But which one provides the best return on investment? Each material offers distinct advantages and drawbacks. Below is an overview to help choose the right one to maximize productivity and profitability in your operation.

Hygiene

Plastic and metal nests are favored for their smooth surfaces and ease of cleaning. However, one must keep in mind that poultry houses are not cleaned often — only in between flocks when a house is empty. Due to the infrequent nest cleaning, other factors can play a larger role in overall house hygiene.

Wood, being naturally porous, can absorb moisture. While this property might seem to increase the risk of bacterial growth, research suggests otherwise. The capillary action in wood can help trap bacteria below the surface, where it then dies. With plastic and metal, bacteria stay on the surface, where it has a greater chance of getting picked up by birds, and it can live longer if moisture is present.

This effect can be seen in university research on cutting boards. For instance, a 1994 study, “Cutting Boards and Food Safety,” by Dr. Dean Cliver with the University of Wisconsin, found that bacteria such as Salmonella and E. coli introduced to wooden cutting boards declined significantly over time, even without cleaning, aided by the porous properties of wood. Dr. Cliver led other research with the University of California, Davis, which had similar findings, showing that plastic cutting boards tended to harbor more bacteria than wood.

Additionally, some types of wood possess natural antimicrobial properties, which can inhibit bacterial growth to an extent. Plastic lacks this ability, which can create a better environment for bacteria to live.

Bird Behavior

The material used for nests plays a significant role in influencing bird behavior, contributing to overall productivity in the number of Grade A eggs produced. Wood is generally known to have an advantage here. The weight, density and other characteristics of wood provide a stable and, most of all, quiet environment for birds. The noise dampening qualities of wood is attributed to higher nest acceptance than both plastic and metal nests.

Wageningen University in the Netherlands reinforced this claim through a study on broiler breeder hens, titled, “Relative preference for wooden nests affects nesting behavior of broiler breeders.”1 This study compared the number of nest and floor eggs between wooden and plastic nests. The study revealed a higher proportion of eggs laid in wooden nests compared to plastic. Camera data also showed a stronger preference for wooden nests, as more birds visibly spent a greater amount of time in them.

Nests constructed of metal create a very loud environment, which leads to even worse nest acceptance than plastic. Most growers understand this disadvantage and, as a result, metal nests are rarely used in broiler breeder operations today.

Durability

An added benefit of wood is its durability. Concerns about potential rot during cleaning are mitigated by the infrequent washing schedules in poultry houses. Since poultry houses are typically pressure-washed less than once per year, the length of exposure to water is minimal. Additionally, these types of nests are made from marine-grade glued plywood with an outer film layer, which is highly suitable for contact with water and wipes down easily when cleaning.

In fact, the porosity of wood is an advantage when it comes to moisture exposure. Even though wood absorbs water, it is also able to dissipate moisture quickly. As a result, wooden nests over 15 years old often show minimal signs of deterioration, even with repeated exposure to disinfectants and detergents.

Plastic, on the other hand, degrades over time. After years of pressure washing and exposure to disinfectants and detergents, plastic nests become brittle and are more likely to break. Also, sheet metal options tend to rust over time, contributing to durability concerns.

It is important to note that not all wooden nests are created equal. The best options on the market are made with multiple layers of high-quality wood, contributing to the high strength, durability and noise dampening characteristics. Cheaper versions likely use fewer layers of wood (for instance, five layers of plywood instead of nine), which lessens some of the benefits.

Environmental Impact

Wood is a renewable resource and can be sourced sustainably, making it a more environmentally friendly option than plastic or metal. This is especially true when sourced from sustainably managed forests.

On the other hand, plastic and metal nests are produced from fossil fuels and minerals extracted from the earth. Because of this, they can be seen as less environmentally friendly options.

Cost

Wooden nests have the highest initial purchase price, followed by plastic and metal. Despite their cost, wooden nests often deliver the best return on investment. Their ability to foster a better environment and improve productivity outweighs concerns about upfront expenses.

Metal nests, while less expensive, aren’t commonly used because of the lower return on investment. Poor nest acceptance and increased floor eggs negatively affect profitability.

Conclusion

Given the importance of nests in a poultry house, choosing the right nest material is essential for optimizing productivity and profitability in poultry operations. Overall, film-faced plywood provides better value than plastic and metal alternatives, due to its natural properties that help create a comfortable environment, minimize bacteria growth, increase longevity of the nests and long-term costs. These advantages are often evident by increased bird welfare and a healthier bottom line.