Modular Manure Belt Cage System for Eggs

Cages That Set the Standard.

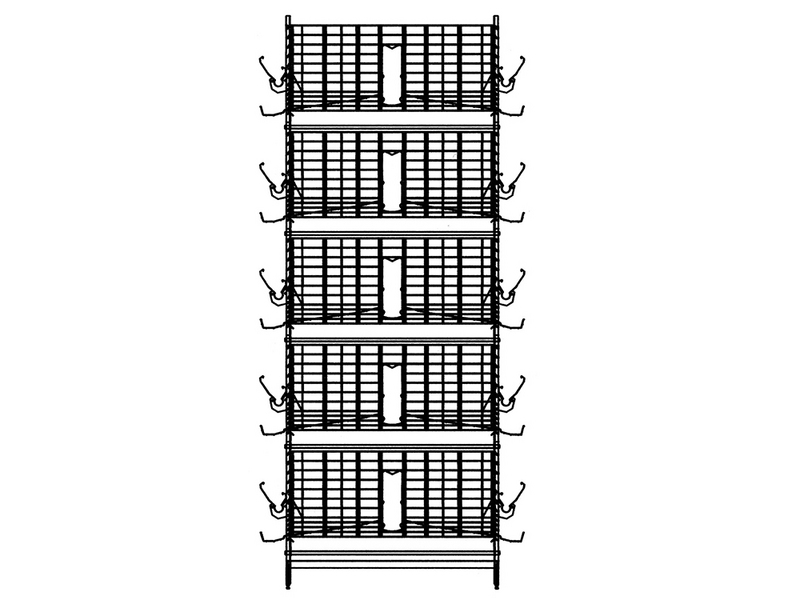

Chore-Time’s Modular Manure Belt Cage System offers egg producers the outstanding production performance they expect from Chore-Time, plus greater shipping simplicity, easier assembly and repair, and improved egg roll-out – all in an economical cage system that meets current bird space standards. Pullet systems are also available.

Chore-Time cages are quality-built in North America. Solid construction and heavy-duty materials combine with our innovative design for years of superior performance.

A composite mesh floor helps lower mortality by using a tighter mesh spacing where birds stand, coupled with a more open spacing in other sections of the floor.

Chore-Time’s metal door latch offers true one-handed operation. Its positive lock means chickens don’t get out.

- Cages are available in 3-high to 12-high models in cage rows up to 520 feet (160 meters) long; walkways and/or step rails are easily integrated.

- Dual floor slope improves egg roll-out, and distance from cage to egg tray helps protect eggs from bird damage.

- Modular design features individual cages instead of eight-foot (2.4-meter) cage sections – makes cage replacement and manure belt access easier.

- Easy assembly features innovative interlocking parts, and requires fewer rings.

- Full-front horizontal cage door provides easier, more comfortable access to feed and to the cage interior.

- For even greater durability, cages and structural components are manufactured using all galvanized steel construction and Galfan® cage floors.*

- Flexible cage floor has tighter mesh spacing in bird standing area and is better for birds’ feet.

- Mesh partitions improve ventilation.

- Floor support is simple solid rod construction. Does not require constant end-row tension.

- System is covered by Chore-Time’s generous cage warranty and solid backing. (See Chore-Time’s full written warranty for complete warranty details.)

*Galfan is not owned or licensed by CTB, Inc. and is the sole property of its respective owner.

Each tier has a separate drive unit with its own motor and can be operated independently of the others as needed.

- Modular construction makes Chore-Time’s system easier to install. Plus, parts are interchangeable between tiers.

- Rubber-coated drive roller is coupled with steel pressure rollers – a combination that allows reliable belt operation on cage row lengths up to 520 feet (160 meters).

- Pressure roller scrapers keep rollers clean for better tracking and improved pull of the manure belt.

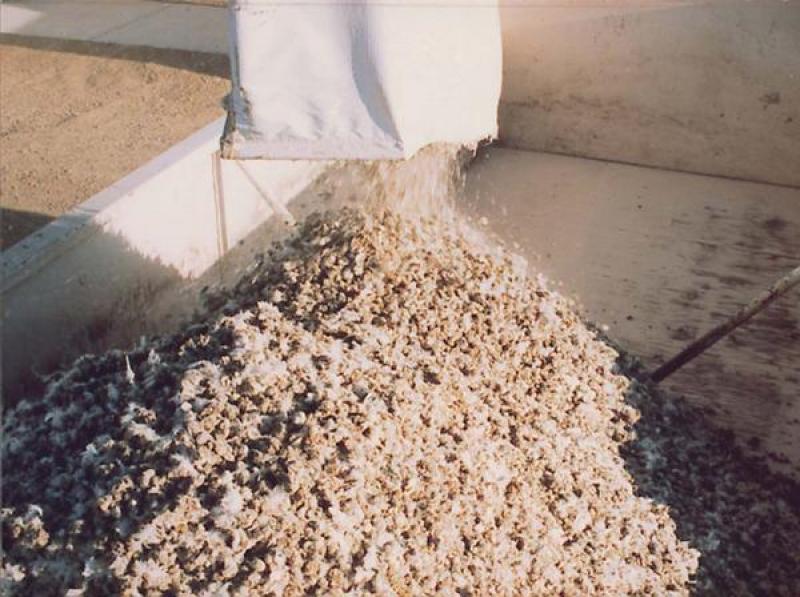

- Plastic belt scraper cleans belt without cutting or damaging it. Each tier’s belt can be cleaned easily and individually.

- Uses the same proven Chore-Time gearheads and motors used in Chore-Time feeders and egg collectors.

- Drive mechanism is designed to protect critical parts from damage should a problem occur.

- Optional air tube includes an integrated drinker catch tray. The big air tube with large holes results in more total air volume across the belt for drier manure and more even air distribution for the hens during minimum ventilation.

- Helps reduce ammonia emissions.

- Exhaust air is low in dust content.

- Modular components offer design and output flexibility.

- Fully automatic system handles air capacities from 4,700 to 8,800 CFM (8,000 to 15,000 M³ per hour).

- Made of the highest quality materials for long life.