White Paper:

New Solutions for Retrofitting Old Houses

Many of the obstacles keeping growers from transitioning from caged to cage-free egg production are simply misperceptions. For instance, many fear the cost is too high but, in reality, a high-performing aviary can usually pencil out a solid return on investment through reliable profitability. As the industry continues to gravitate toward cage-free eggs, the decision to stay with cages may be far more costly in the end.

One of the other obstacles, however, is literally an obstacle. Many older high-rise poultry houses have low clearances, especially along the sidewalls, which have limited the installation of some multi-tier aviary systems – until now.

The Problem

When converting an existing poultry house to cage-free egg production, some growers have not been able to fit multi-tier aviaries under their pitched roofs. And, if the aviaries do fit, they may not provide enough clearance between the aviary and the roof to provide an adequate amount of ventilation needed to maintain a healthy environment.

As a result of these challenges, the growers may have had to sacrifice efficiency by not maximizing their available space. Or, they have settled for installing a lesser-performing system, such as a floor layer setup.

Growers who convert barns to a floor layer system due to height limitations sacrifice return on investment. Floor systems have much lower bird density and require more labor.

Advantages of the Multi-Tier Design

Growers wanting to retrofit existing houses with multi-tier, or European-style, aviaries are well advised. That is because this design is proven to have higher bird performance and lower labor requirements than other cage-free systems. In fact, many experts believe multi-tier aviaries are the future of cage-free egg production.

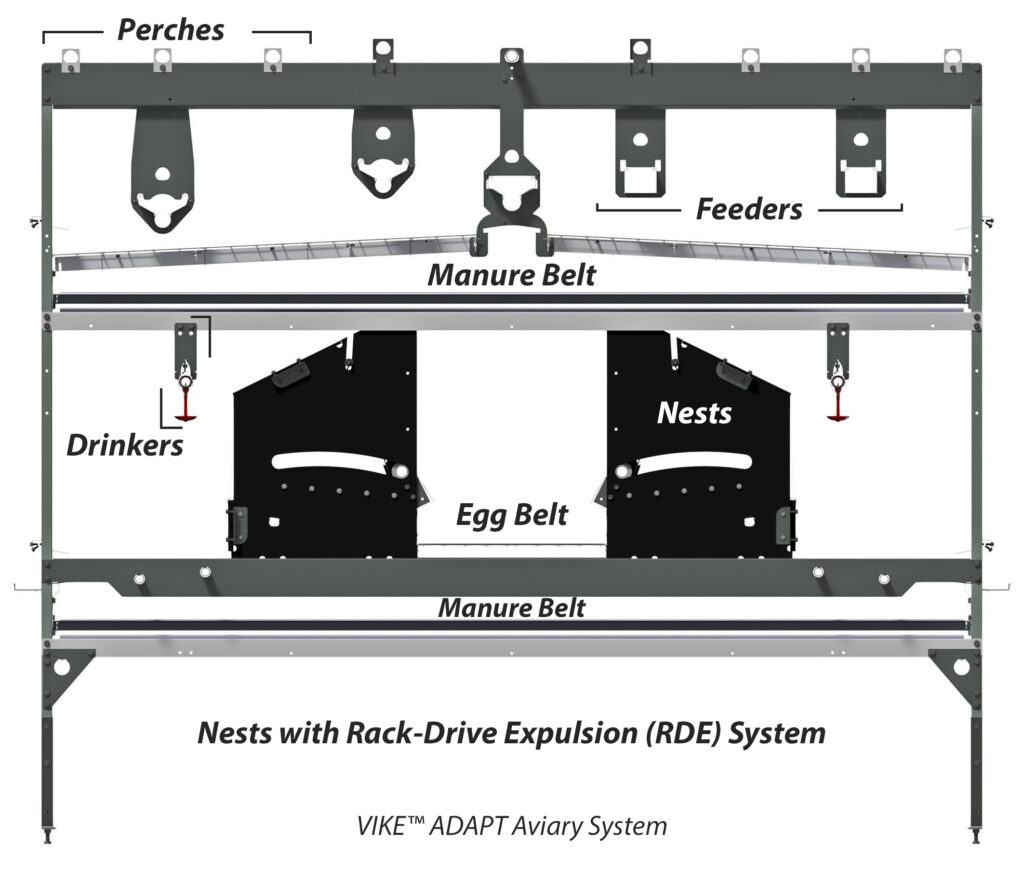

Birds perform well in multi-tier aviaries because they encourage natural behavior. One example of this is the three-tier VIKE™ Aviary System from Chore-Time.

The lower level has feeding and is counted as additional floor space. Birds have access under the system to move around, dust bathe and scratch. The middle level has water in front of the nests, which has been associated with producing a higher percentage of Grade A eggs. The top level has feeding and perches, where birds naturally like to spread out to sleep at night.

Since their inception in the Netherlands, multi-tier aviaries have proven themselves over decades of use. Throughout the years, multiple configurations have been developed, including low-profile designs. Nonetheless, many existing poultry houses are still unable to accommodate three-tiered aviaries at the lowest points.

The Solution

As more North American growers transition from caged to cage-free eggs, engineers have taken note of the height challenge and began developing solutions to modify multi-tier systems to better fit low-clearance houses. A new, leading solution is to merge the bottom and middle levels, creating a two-tier aviary.

An example of this is Chore-Time’s ADAPT System. At less than 84 inches tall, it fits well in many low clearance building situations.

Despite the shorter size, the two-tier aviary maintains many of the same advantages of the original three-tier design. Additionally, it meets cage-free requirements worldwide.

There are two keys to the high performance of the two-tier model:

- Perches are kept on the upper level.

- Water is still located in front of the nests.

The top level, with perches and feeding systems, provides an ideal sleeping environment. This helps provide good ventilation and eliminate hot spots in the house. In the morning the birds will wake up, feed on the upper level and get thirsty. Then, they move to the lower level to find water. After drinking, the birds naturally find their way to the nests to lay eggs. Instead of a lower level with feeding, these two-tier aviaries have a manure belt under the nest level with a wide platform in front of the nests. Not only does this design provide ample space for natural bird activities, but it also keeps a clean environment with minimized ammonia levels, thanks to the manure belt.

To match the width and varying heights of a building, multiple aviary configurations can be used in one poultry house.

For instance, the Adapt system can be used along the walls, where clearance is lowest. Then, a three-tiered VIKE Aviary System can be used in the center of the house, where the roof peak provides more room.

Properly trained birds enjoy moving across the aisles from one level to the next, resulting in excellent welfare and high performance. Growers who implement this system find that birds use it instinctively well, minimizing hot spots and floor egg issues that are common with other aviary types.

As pressure mounts to convert existing poultry houses to cage-free egg production, manufacturers continue to meet these challenges with new flexible equipment solutions. Today, multi-tier aviaries can accommodate practically any poultry house width and roof clearance.

As a result, growers no longer need to make sacrifices due to the design of their existing buildings. One can say they are no longer “caged” into making compromising decisions.